THE SCIENCE BEHIND ARTDESHINE

COATINGS

SiO2 glass ceramic quartz crystal

ALL THE SAME

Most surface protection coatings are made using many different silicon based polymers and silanes, that all contain silicon (Si) groups including SiO2.

This is the reason why manufacturers affix names like GLASS, CERAMIC, QUARTZ, CRYSTAL to their products since these are derived from SiO2. They are simply just names for ease of marketing.

All of Artdeshine’s coating formulations utilizes the same silicon based polymers and silanes as with many other brands/manufacturers. We call some of our products “ceramic coatings” too.

GRAPHENE COATING?

- SAME base silicone polymer coating

- Is NOT made from graphene

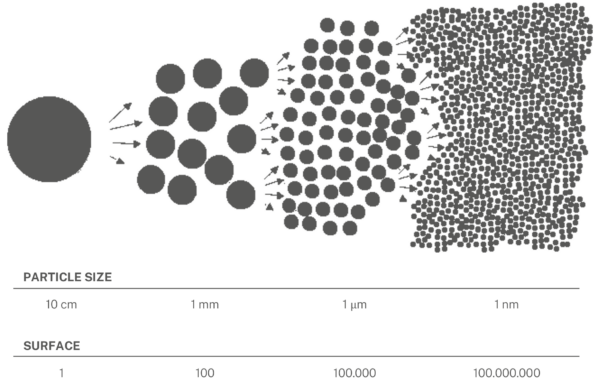

- Graphene Oxide processed to NANO size

Even our graphene coatings are no exception. They are still silicone based polymer coatings. We disperse Graphene Oxide (GO) that are processed into nano sized particles smaller than 1 micron into the formulation, hence the name. To compare, a strand of human hair is about 50 microns. The coating itself is NOT made from Graphene.

There is no need for special types of graphene materials as they all perform the same function as an additive in a silicone polymer coating. With nano sized particles, we are able to increase the particle count of graphene oxide to provide a higher concentration and coating surface coverage.

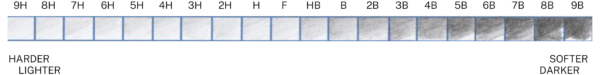

Ability to resist 9H pencil scratch

Hardness is rated by various other methods

LESS FRICTION LESS FORCE = LESS MARRING

As most coatings are made to cure very hard, they are often touted as anti-scratch solutions. This is very far from the truth. Indeed as a thick piece of cured sample, the scratch resistance capability is exhibited clearly. However as a thin film coating applied by hand on substrates like automotive bodies, this capability is negligible. Artdeshine works around by decreasing the amount of friction on a coated surface. Our coatings are made super slick to reduce friction that will in turn lead to reduced marring.

PENCIL GRADES

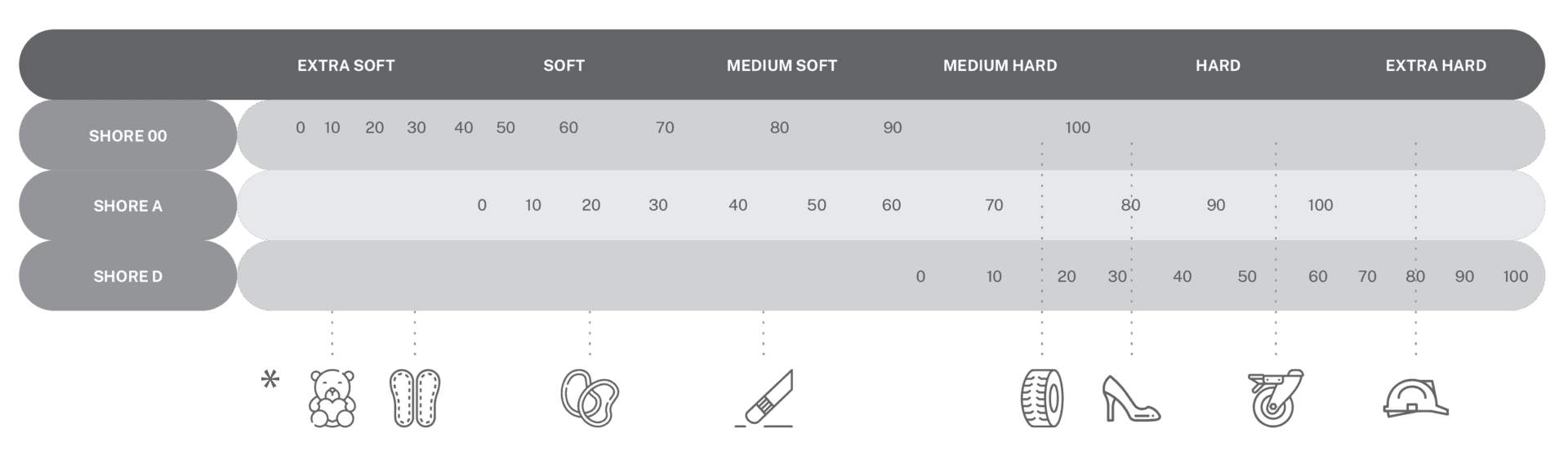

SHORE A HARDNESS

Alternative measurement of polymer hardness

Artdeshine’s silicone polymer coatings, INCLUDING Nano Graphene Coating is made to be

flexible and tensile, with a measurement of about 80-95 using the SHORE A hardness scale.

* Teddy Bär, Schuhsohle, Ohrring, Bleistift, Reifen, Schuhe, Räder, Helm

WATER-SPOTS

WATER-MARKS

ETCHING-MARKS

• Caused by combination of liquid, heat/UV, contaminants

• Rain, bird poo, tree sap, salts, oils

• Permanent dulling

• Removable only by abrasive polishing

These spots/marks are caused by contaminants etching into the clear-coat

or even matte/gloss PPF. When rainwater mixes with contaminants like

bird poo, tree sap, salts and oils, heat/UV aggravates the chemical reaction.

They then slowly etch or corrode the surface.

UP TO

80 % REDUCTION

The unique polymer composition of our coatings helps to slow down and

reduce the chances of etching/corrosion significantly. This is because of

the dense polymer structure resulting in less microscopic “holes” for

contaminants to settle in.

Graphene Oxide as an anti-corrosion material helps to fight off spotting

issues by reinforcing the polymer coating.

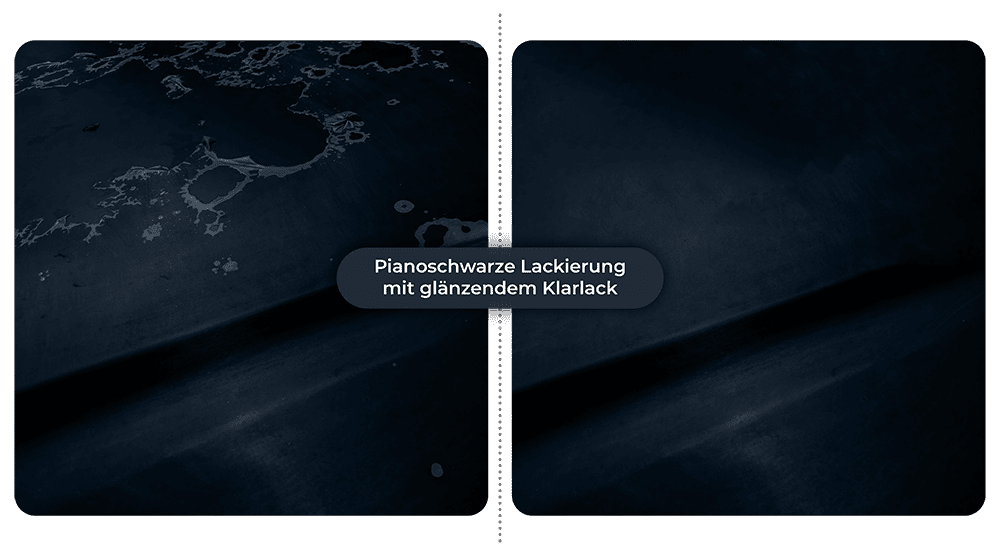

White paint with gloss clear coat

2 months weathering test, no washing.

UN-TREATED

ARTDESHINE NANOGRAPHEN-BESCHICHTUNG

UN-TREATED

ARTDESHINE NANOGRAPHEN-BESCHICHTUNG

HYDROPHOBIC

ANTI-STATIC

REPELLENT & SLICK

With a very hydrophobic, repellent and slick surface enabled by our

coatings, liquid/contaminants are less able to stay on the surface.

The surface area covered by concentration is reduced significantly.

Even when contaminants react with the liquid substances and

heat/UV to etch or corrode, the surface area affected is minimal.

White paint with gloss clear coat

Dirt Pick Up Resistant (DPUR) test according to ASTM D3719 standards.

ENHANCED GLOSS

COMPATIBLE WITH

PPF/VINYL WRAPS

Our coatings fill up microscopic imperfections of a surface.

This enables light to reflect more, bringing to your eyes

a more saturated, bolder colour and a sense of “deeper”

reflection. They do not change the colours of surfaces,

only to enhance or look darker in tone.

UNBEHANDELT

ARTDESHINE NANOGRAPHEN-BESCHICHTUNG

UNBEHANDELT

ARTDESHINE NANOGRAPHEN-BESCHICHTUNG